Undoubtedly, producing and purifying a protein is an art form.

Indeed, each recombinant protein (rec. protein) to be produced in vitro has specific characteristics and singularities, which makes its production and purification absolutely challenging. In this post, I’d like to share some tips and review basics for optimizing experimental design when producing functional recombinant proteins and working on protein purification.

Since 2000, tebu-bio provides protein services from production to purification, we can help you further determine the most appropriate strategy by considering all parameters and following experimental requirements.

The keys to producing a functional and pure rec. protein

One of the major endgames is the production of a protein in its native conformation, and therefore correctly folded. It goes without saying, that good knowledge of the protein of interest is a major asset.

Performing a feasibility study with bio-informatics eases the designing of the ideal process. This study includes the determination of the number of disulfide bridges, the identification of glycosylation sites, the obtaining of solubility and stability probabilities, the analysis of predictive secondary and tertiary structures… In short, it provides valuable information to successfully carry out the steps related to protein purification.

In this way, a project that has every chance of succeeding always starts with an in-depth analysis, allowing the selection of an adequate production system like:

- The use of bacterial strains capable of forming disulfide bridges in their cytoplasm or producing toxic or unstable proteins,

- The use of human cells (eg. HEK293 EBNA cells) to produce functional rec. proteins closest to in vivo context thanks to post-translational modifications (like glycosylation) and the presence of adequate chaperone proteins.

Protein purification: Purity, always more purity…

Protein purification isn’t always easy. There is a large variety of resins available. The most used are:

- Affinity resins (protein purification via the tag or the interaction with a partner)

- Ion exchange resins (protein purification via protein charge)

- Hydrophobic resins (protein purification via protein hydrophobicity)

- Molecular sieve or gel filtration (protein purification via protein size)…

In case of non-tagged or barely purifiable proteins, the conception of innovative protein purification strategies is essential. Indeed, the optimization of this step, in terms of cost and time while minimizing the number of steps, but also in terms of efficacy, is indispensable.

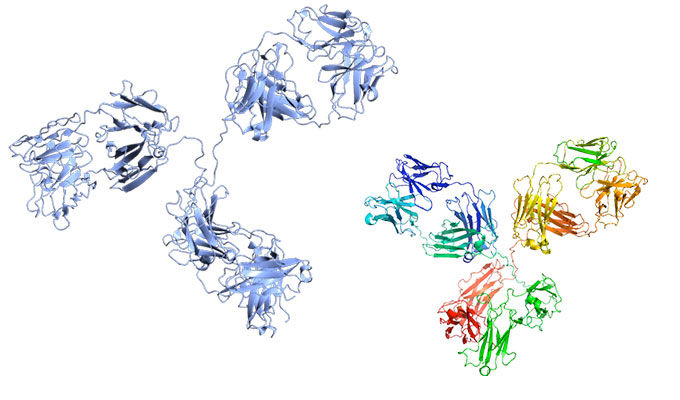

Thus, the use of resins such as “mixed mode” resins or resins on which the targets of the protein of interest (incl. monoclonal antibodies (Mabs)) are effectively coupled is preferable. This avoids the multiplication of purification steps, the loss of purified material by precipitation, as well as the time allocated to experiments. Certainly, this requires developments that can be easily implemented if a well thought “DoE” or design of experiments is elaborated beforehand.

After protein purification: the story doesn’t end here…

Even after the collection of the protein of desired purity, it’s not the end of the story – quality control, such as a western blot with validated primary antibodies, an activity test, the characterization of protein-protein interactions (ELISA, Isothermal Titration Calorimetry (ITC), Cell-Based Assays such as BPS Bioscience’s PD-1 Immune Checkpoint Cell line to investigate PD1 pathway or screen PD1 inhibitors…), and/or rate measurement of endotoxins, cannot be neglected.

More tips for rec. protein expression and protein purification

If you are looking for more ways to improve your rec. protein production and protein purification steps, you can check out our other posts on the subject:

- How to choose the perfect buffer to get a pure, stabilized, functional protein

- Gel Filtration – Which column to choose for your size exclusion purification?

- How to easily purify your proteins with adapted magnetic beads…

- Why will mixed mode resins revolutionize R&D scales mAb production?

- Which bacterial strains for recombinant protein expression?

- Which endotoxin testing assay in bioproduction?

- How to easily obtain a highly purified untagged recombinant protein

tebu-bio supplies tools and expertise capable of providing the keys to success of rec. protein expression and protein purification projects by offering services from molecular biology to cellular biology and protein biochemistry. Don’t hesitate to contact me with your questions and comments through the form below to further discuss your rec. protein project.