In a previous post, we looked at innovative methods to assess immunogenicity in biotherapeutics and biosimilars.

The objective though, is to have the least immunogenicity possible (exception made for vaccines). Some factors, especially those which are patient-related, cannot be always controlled but some can definitely be monitored during the production processes of biotherapeutics and biosimilars. Let’s take the case of Host Cell Proteins (HCPs).

A brief overview of Host Cell Proteins or HCPs

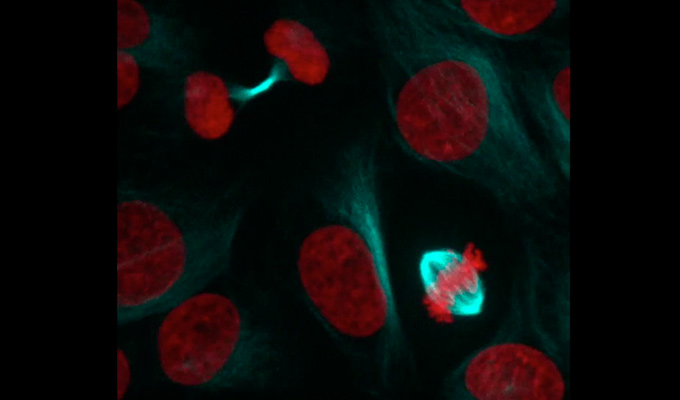

Biotherapeutics (biologics and biosimilars) are produced by “biofactories”, i.e. they are made in living host organisms. This means that, most probably, proteins present in these biofactories (ie. the Host Cell Proteins) will be present in the final preparations on the biologics. These HCPs may lead to undesirable effects, especially related to immunogenicity. This is an important factor, as it may affect the approval of the biological entity for medical use (1).

Identity and content on HCPs may be influenced by different factors, including type & strain of expression system (e.g. E. coli, CHO, NS0…), the manner in which the biologic of interest is expressed (e.g. periplasm vs cytoplasm), isolation & purification process as well as on the biologic molecule being expressed…

The amount of HCPs is expressed in ng of HCP per mg of protein (ng/mg) or parts per million (ppm), and it should be at the lowest possible level.

In any case, regulatory bodies (European Medicines Agency European Union agency (EMA) and the U.S. Food and Drug Administration (FDA)) demand that the amount of HCPs be identified and quantified (2). The reason for this is that the foreign (i.e. non-human) nature of HCP has the potential to elicit an immune response. Monitoring impureties (such as HCPs) during in manufacturing and purification bioprocesses is then crucial; these steps being continuously improved.

Strategies to analyse HCPs

Numerous strategies to analyse HCPs are available (from proteomics to immuno-assays and bio-IT…). Each of them has their advantages and disadvantages.

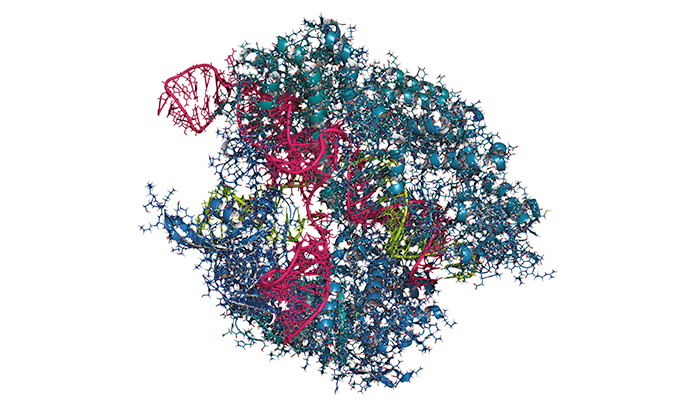

Techniques based on Proteomics (such as MS and its variations) seem to be the most accurate ones (3), but their use may be expensive and a high degree of expertise is required. In fact, sometimes it is necessary to develop different techniques depending on the stage over the workflow (discovery stage, production, QC…). (4) In addition, routine quality control of a manufacturing process may be tricky for some laboratories.

For most industrial laboratories, a combination of generic (usually commercial) and customised (usually proprietary) solutions are used to quantify HCP levels in the biological preparations. Though the accepted value for HCPs ranges from 1 to 100 ppm, the fact is that the acceptable levels for HCPs vary according to the intrinsic properties of the biologic entity, as well as its route of administration, dosage, treatment length (acute vs. chronic) etc…

WB and ELISA continue to be the most commonly used techniques for HCP testing because of their ease of use and robustness. This is particularly the case for ELISA which enables quantification. Assays measuring the release of inflammatory cytokines may also be used to assess the immunogenic potential of the remaining HCPs in the preparations (but that will be the topic for another post !).

Let’s take a closer look at different solutions for HCP monitoring, including commercial and customised antibodies for WB, as well as ELISAs.

HCP analysis with antibodies for Western Blotting

For WB, classical generic antibodies for detection of HCP, either in SDS-PAGE or 2D electrophoresis can be used (e.g. anti-HCP from E. coli or from CHO). In all cases, it is important that antibodies are raised against sound HCP preparations, such as those without IgGs, or from a null cell line (i.e. not expressing the biologic of your interest) to avoid any cross-reaction or interference (5).

Primary antibodies for WB can be either unlabeled or labeled. The use of the second option is recommended for mAbs expressed in CHO or NS0 cells.

Some tools include:

- anti-HCP from E. coli / CHO, unlabeled

- anti-HCP from E. coli / CHO, biotin-labeled

- HCP standards for E. coli / CHO

In some cases, though, it may be necessary to develop customised antibodies for a specific project.

In this situation, it’s important to choose companies known to have an expertise for this kind of development, as anti-HCP have some requirements that other antibodies do not have (e.g. development of robust HCP standards to be used as immunogens). Time and cost should be also taken into account when developing a custom HCP program. Experts at tebu-bio are used to working with researchers to design the most appropriate project, which can include fractionation into HMW and LMW HCPs, or no processing and then cascade IP.

HCP analysis by ELISA

ELISAs remain the most common technique used for HCP testing because of their convenience and good precision. Also, it’s quantitative, which provides numerical results that are amenable for setting control limits and specifications.

As for antibodies for WB, one can use generic solutions, or develop proprietary immunoassays for the specific biotherapeutic.

Examples of classical generic ELISAs include:

It is also possible to develop a specific customized ELISA.

Generic or custom solutions to monitor Host Cell Proteins – “one size does not fit all”

What is clear is that HCP programs must be implemented early in the development cycle, to avoid any potential risks and lack of process robustness. In general, classical “generic” options will be faster and cheaper to implement than customised solutions. A generic assay should be used during process development and as a lot release test (6).

Customised assays cannot be developed until the production process has been validated, and although they can provide some help in determining process control, they may give redundant information vs. a generic assay.

It’s important to take into account that antibody or immunoassay development programs can take up to 8-12 months, and their cost can range from 5 to 100 k€! So it should be decided on a case-by-case basis (e.g. when a defined and problematic HCP contaminant persists).

Do you need any help in designing the best HCP program for your specific biologic / biosimilar?

No panic, experienced teams of specialists in the field of bioproduction and HCP measurements are easily reachable. You might like to talk with them about the best solutions for your projects. Just fill in the contact form below or leave a comment of this post!

[contact-form to=’ana.arraztio@tebu-bio.com’ subject=’Please contact me for further information about the best HCP program for my biosimilar’][contact-field label=’Name’ type=’name’ required=’1’/][contact-field label=’Email’ type=’email’ required=’1’/][contact-field label=’Comment’ type=’textarea’ required=’1’/][/contact-form]

Publications related to Host Cell Proteins and Immunogenicity

- European Medicines Agency, author. Alpheon: Scientific Discussion (2006).

- ICH Harmonised Tripartite Guideline, author. Specifications: Test procedures and acceptance criteria for biotechnological/biological products Q6B. (1999).

- Schenauer M. R. et al. “Profiling the effects of process changes on residual host cell proteins in biotherapeutics by mass spectrometry” (2013) Biotechnol Progress, 29: 951–957. doi: 10.1002/btpr.1748.

- Doneanu C.E. et al. “Analysis of host-cell proteins in biotherapeutic proteins by comprehensive online two-dimensional liquid chromatography/mass spectrometry” (2012) mAbs-Report 4(1): 24–44. doi: 10.4161/mabs.4.1.18748.

- Wang X. et al. “Host cell proteins in biologics development: Identification, quantitation and risk assessment” (2009) Biotechnol. Bioeng. 103: 446–458. doi: 10.1002/bit.22304.

- Hoffman K. “Strategies for host cell protein analysis” (2000) Biopharm. 13:38–45.