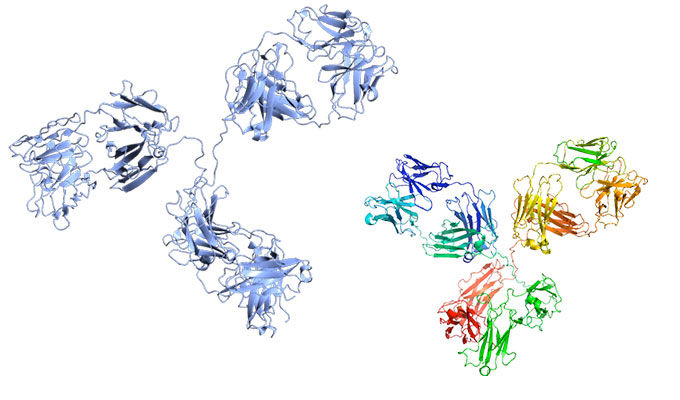

Monoclonal antibody (mAb) engineering and their development as therapeutic or diagnostic tools have become the must in pharmaceutical industry, in medical biotech and in the research world. Purification of this type of biosimilar requires a particular know-how.

This guide is aimed at introducing experimental purification methods initially optimized in GMP-grade mAb bio-production facilities to R&D scientists. This is made possible by bringing purification methods already validated in GMP industrial processes to R&D scientists. Such an approach will offer protein biochemists unequalled advantages in designing efficient and straightforward recombinant protein purification tools. Interestingly, pilot studies performed in R&D scale production will be more easily transferred to GMP scale processes.

In the environment of recombinant proteins and mAb bio-production, the corner stone is related to the question “How to optimally purify a mAb?”.

Mixed-mode chromatography resins have recently been released for multimodal chromatography to meet large-scale bio-production standards at any stage in the recombinant protein purification process (initial capture of mAbs, polishing step of mAb purification…).

Nowadays, it’s relatively easy to transpose those GMP-grade multimodal chromatography protocols to R&D developments and vice-versa.

Thus, you can benefit early on in the validation stages of their highly selective properties and high resolution separation of your recombinant proteins.